Researchers at Tohoku University have developed a new method to predict the performance of metal-nitrogen-carbon (MNC) molecular catalysts, critical to the advancement of fuel cell technology. Their study highlights a new predictive tool that relies on computer simulations to study interactions between electric fields and pH levels. This advance opens a more efficient way to develop catalysts that work efficiently under different environmental conditions, potentially overcoming one of the main obstacles to the widespread adoption of fuel cell technology.

Tohoku University researchers have developed a method to predict the performance of new catalysts for fuel cells, potentially speeding up the development of more efficient clean energy solutions.

Tohoku University researchers have created a reliable way to predict the performance of a promising new type of catalyst. Their discovery will accelerate the development of efficient catalysts for alkaline and acidic environments, saving time and effort in future efforts to create better fuel cells.

Details of their research were recently published in the journal Chemical science.

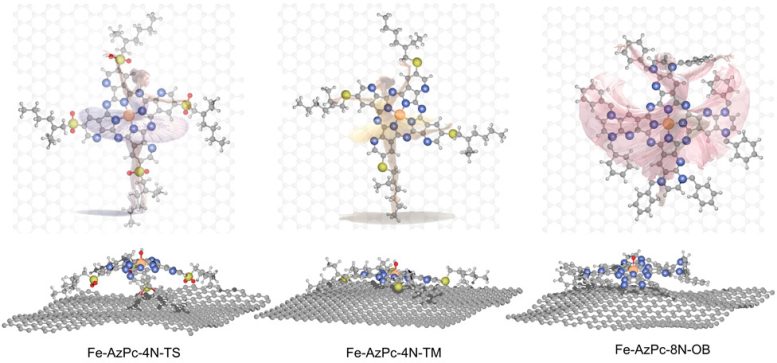

Structures of long-chain Fe-azaphthalocyanine (AzPc) molecular catalysts. After DFT geometry relaxations with more than 650 atoms, different “dance patterns” appeared due to different interactions between the molecular side chains and the graphene substrate. Credit: Hao Li, Hiroshi Yabu et al.

Fuel cell technology is often touted as a promising clean energy solution; however, problems with the efficiency of the catalyst prevented its widespread use.

Metal-nitrogen-carbon (MNC) molecular catalysts possess characteristic structural properties and excellent electrocatalytic performance, especially for the oxygen reduction reaction (ORR) in fuel cells. They offer an economical alternative to platinum-based catalysts.

Unique properties of MNC catalysts

One such variation of MNC catalysts is metal-doped azaphthalocyanine (AzPc). They possess unique structural properties, characterized by long-lasting functional groups. When these catalysts are placed on a carbon substrate, they take on three-dimensional shapes, much like a dancer placed on a stage. This shape change affects their efficiency for ORR at different pH levels.

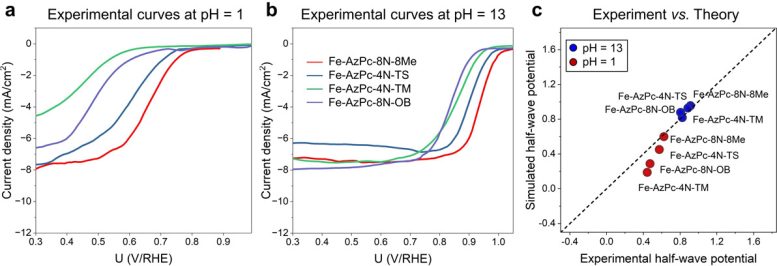

Experimental RDE polarization curves are given at pH = 1 and pH = 13. This figure provides direct comparisons between experimental and simulated half-wave potentials. Credit: Hao Li, Hiroshi Yabu et al.

However, translating these beneficial structural properties into increased performance is a challenge that requires significant modeling, validation, and experimentation, which is resource-intensive.

“To overcome this problem, we used computer simulations to study how the performance of Fe-AzPcs catalysts on carbon for oxygen reduction reactions changes with different pH levels, examining how electric fields interact with pH and the surrounding functional group,” says Hao Li , associate professor at the Institute for Advanced Materials Research (WPI-AIMR) of Tohoku University and corresponding author of the paper.

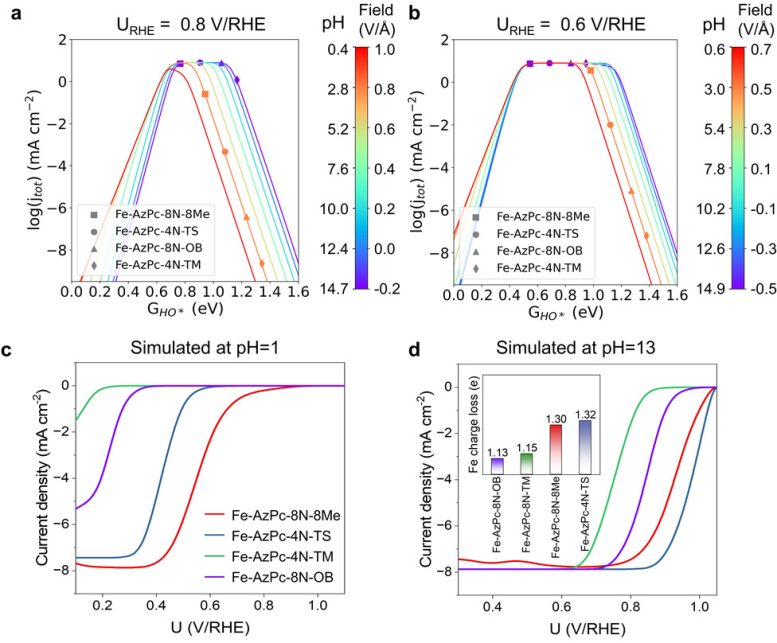

pH-dependent ORR models of volcanoes and simulated LSV curves of Fe-AzPc derivatives. Volcanoes dependent on the pH field. The left and right sides of the colored bar represent the correlation between electric field and pH. This image serves as a reference for our experiments. Credit: Hao Li, Hiroshi Yabu et al.

In analyzing the performance of Fe-AzPcs in the ORR, Li and his colleagues included large molecular structures with complex long-chain arrangements, or “dance patterns,” with an arrangement of more than 650 atoms.

Importantly, experimental data revealed that microkinetic modeling combined with a pH field closely matches the observed ORR efficiency.

“Our results suggest that an estimate of the charge transfer occurring at the Fe site, where Fe atom typically loses about 1.3 electrons, could be a useful method to identify suitable surrounding functional groups for the ORR,” adds Li. “Essentially, we created a direct benchmark analysis for a microkinetic model to identify MNC catalysts effective for the ORR under different pH conditions. »